The mechanical engineering course in Szombathely stands out among the region’s technical courses because of its modern, 21st century laboratory facilities, which support practical teaching to complement theory.

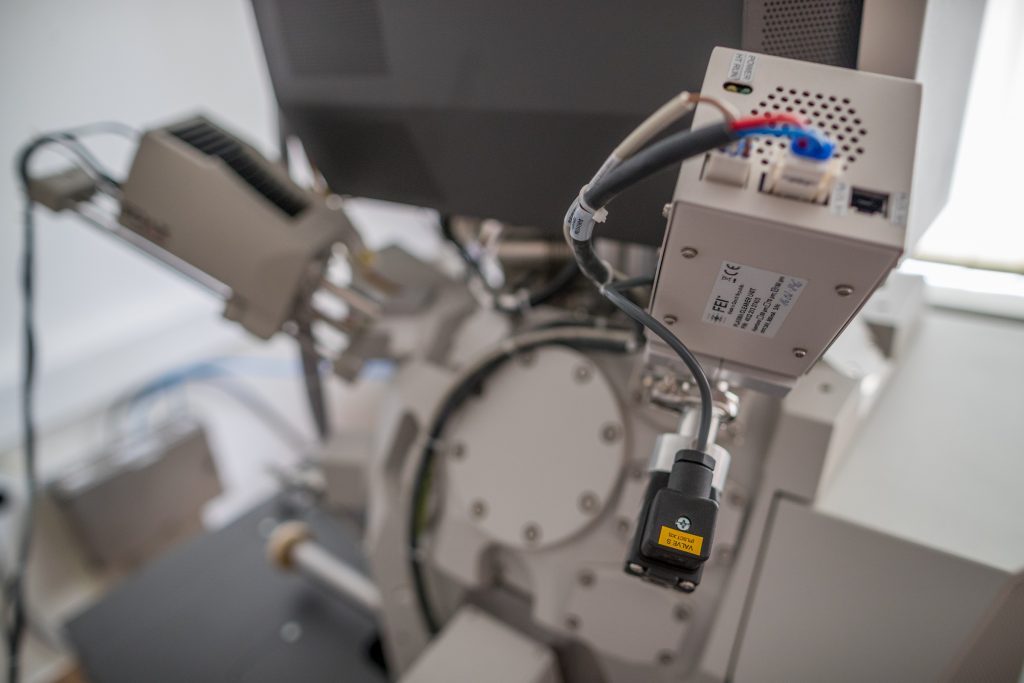

The electron microscope is capable of magnification of up to four million times, allowing the structure and elemental composition of materials to be studied at the micro and nano scale. We can see the crystal structure of matter at a resolution that is unique in Hungary. Based on the crystal structure, we can determine the changes in material properties, which is extremely important for material development, but also a great help for a better understanding of existing materials.

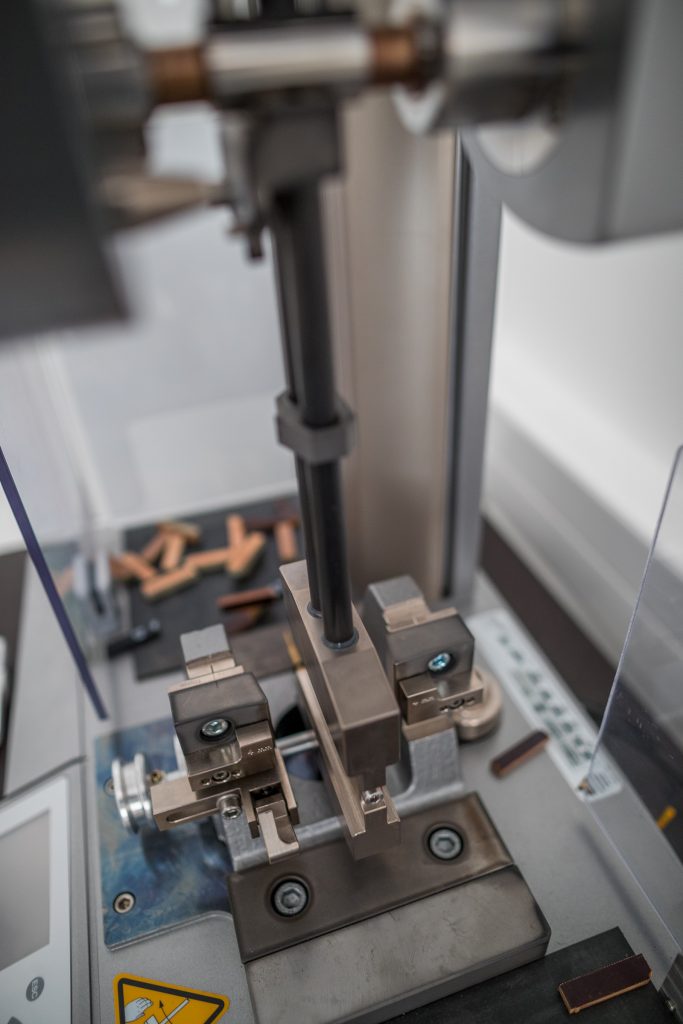

The mechanical behaviour of the material can be studied at macro, micro and nanoscale. We use our specialised computer and Charpy finger to investigate the macro properties. The special feature of our Tissue Computer is that it can determine the deformation of a sample in two directions instead of just one, which provides significantly more information about the material behaviour, allowing us to create more accurate finite element models and better engineering designs.

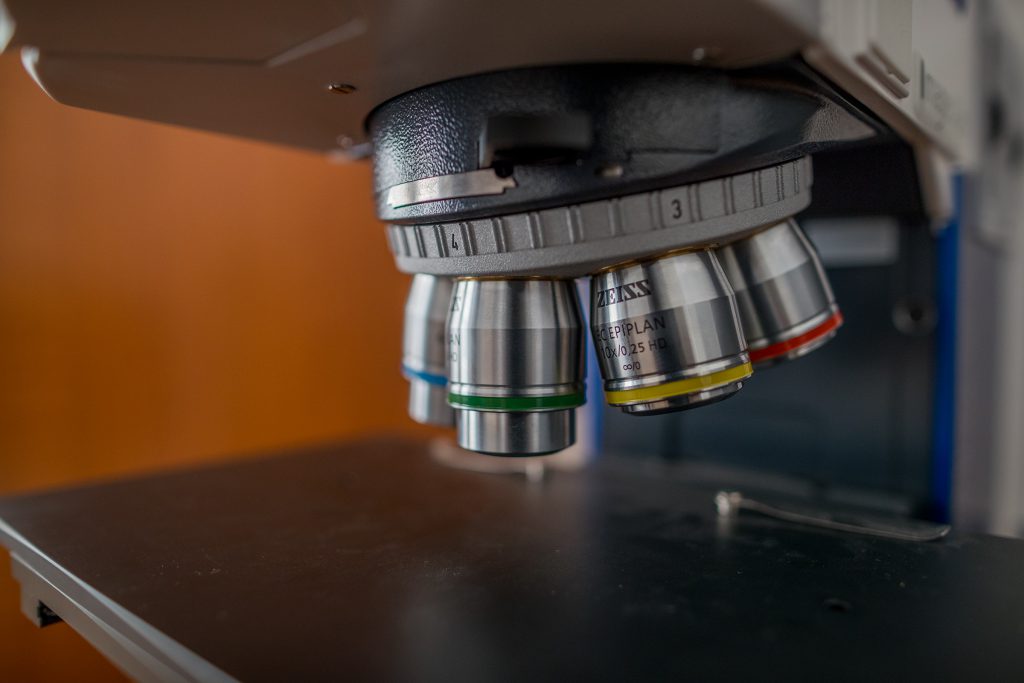

The Charpy yoke in our lab is used for specimen fracture and dynamic strength tests. Testing can be performed over a wide range of temperatures, varying from -70°C up to +300°C. For micro properties testing we use our micro hardness measuring machine, which allows us to monitor the structural changes in the cross section of the material caused by certain effects (e.g. heat treatment, welding, bending, etc.).