The teaching of Vehicle Science at ELTE SEK has been divided into two laboratories, for easier handling and better separation of materials.

In order to focus on practical training in this area, a Lincos scissor lift has been installed in the production technology laboratory in Building C, which can be used by both instructors and students at any time to carry out maintenance work on their vehicles by prior arrangement. From an educational point of view, the lift will be used to demonstrate different vehicle solutions in order to improve accessibility to vehicle structures. A fume extraction unit has also been installed next to the lift to carry out diagnostic operations for engine running. The section also includes a high capacity fan to reduce the extra heat generated.

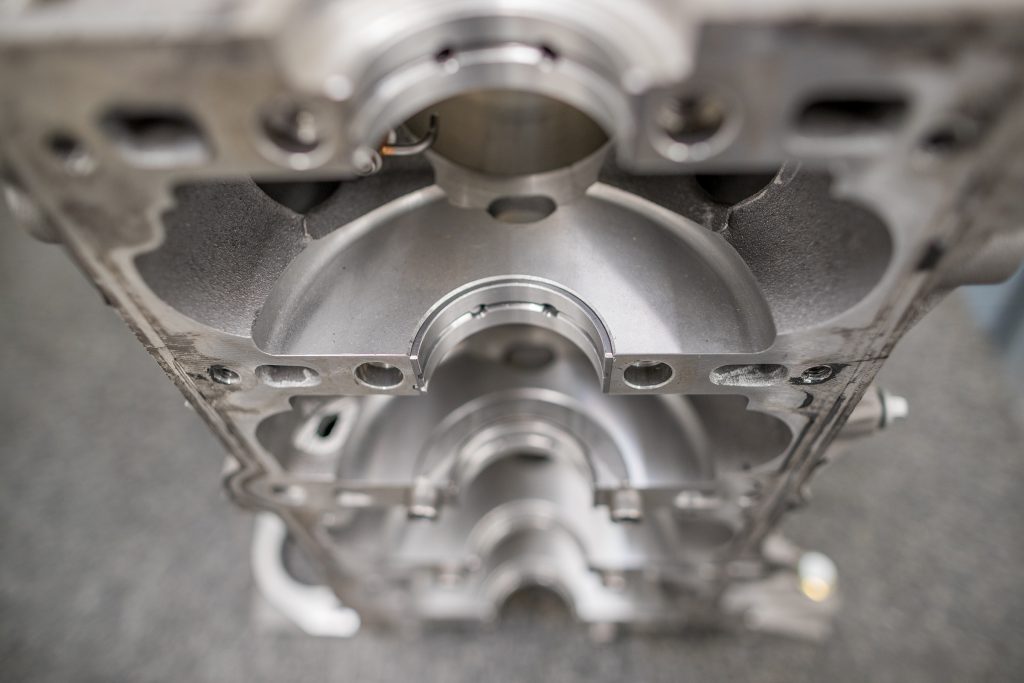

As regards the theoretical part of the site, the vehicle mechanics laboratory in the basement of Building B provides a suitable place to learn the various assembly and diagnostic basics.

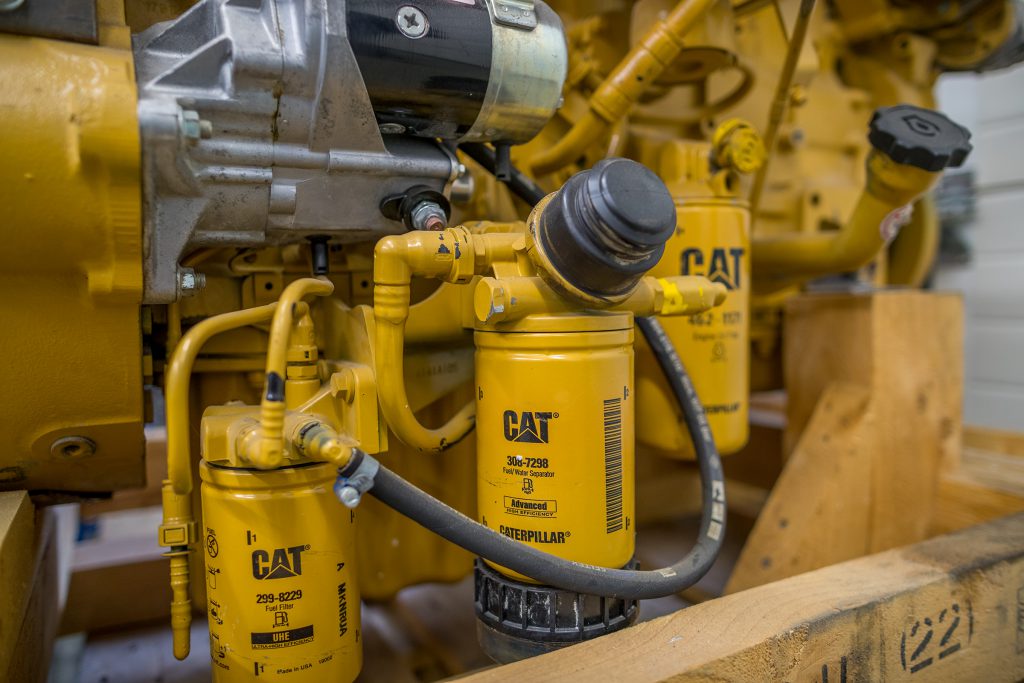

A modern AVL 420 Slim OBD scanner with flue gas and smoke analyser is installed in the lab. The manufacturer has also equipped the unit with a diagnostic module for NOx measurement, as requested. The device is able to connect to the ECU and on-board computer of vehicles equipped with on-board diagnostics (OBD from 1996 onwards) via EOBD standardised transmission. It is also capable of reading fault codes and retrieving freeze frame data to facilitate maintenance and fault analysis. Our flue gas analyser is designed to analyse the emissions of vehicles with quantitative control, i.e. the concentration of CHx, NOx, COx particles to the nearest thousandth (ppm). Our fume analyser is the accepted measurement technology in the automotive industry for the analysis of particulate matter from quality controlled machinery (opacimeter).

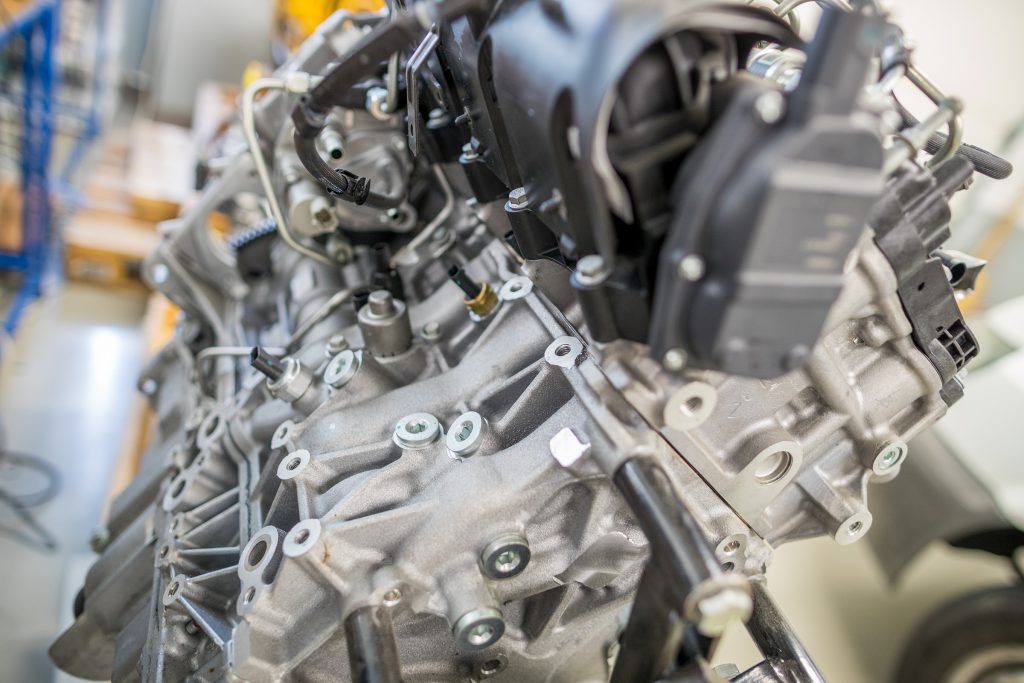

Our instrument, based on the Beer-Lambert light intensity measurement, shows the opacity “K” (%) of the medium (in this case the exhaust gas), which is essential for the technical test, based on the light absorption coefficient “k” (1/m). In addition, the equipment of the room was provided by BPW with agricultural vehicle suspension, braking and drive systems; Schaeffler with clutches and planetary automatic transmissions; and Opel with 7 donated aggregates.

The lecture also included dismantled parts of a former service Volvo S40, courtesy of the University, and, with the help of our Dean Zoltán Horváth, components of a decommissioned Lada Samara to facilitate education and understanding of the structures. As with the practical lab, the theoretical session is free to visit and can be used by prior arrangement by both students and colleagues to facilitate their various assembly and failure analysis work.