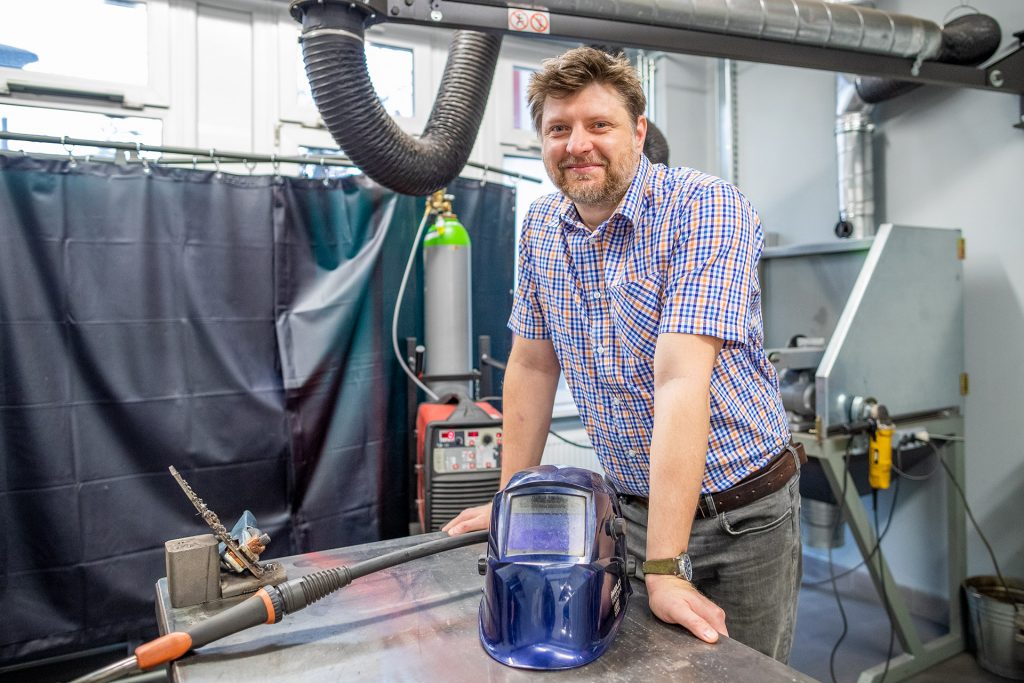

In the field of welding and related technologies, there are many known processes and types of equipment, the best-known of which are the technical applications that students of mechanical engineering can learn about in the course Manufacturing Technology 2. The equipment is also used to produce test pieces for research work. By completing the course, students will gain theoretical knowledge, practical experience in the operation of the different types of equipment and the basics of technological design for welding and allied processes.

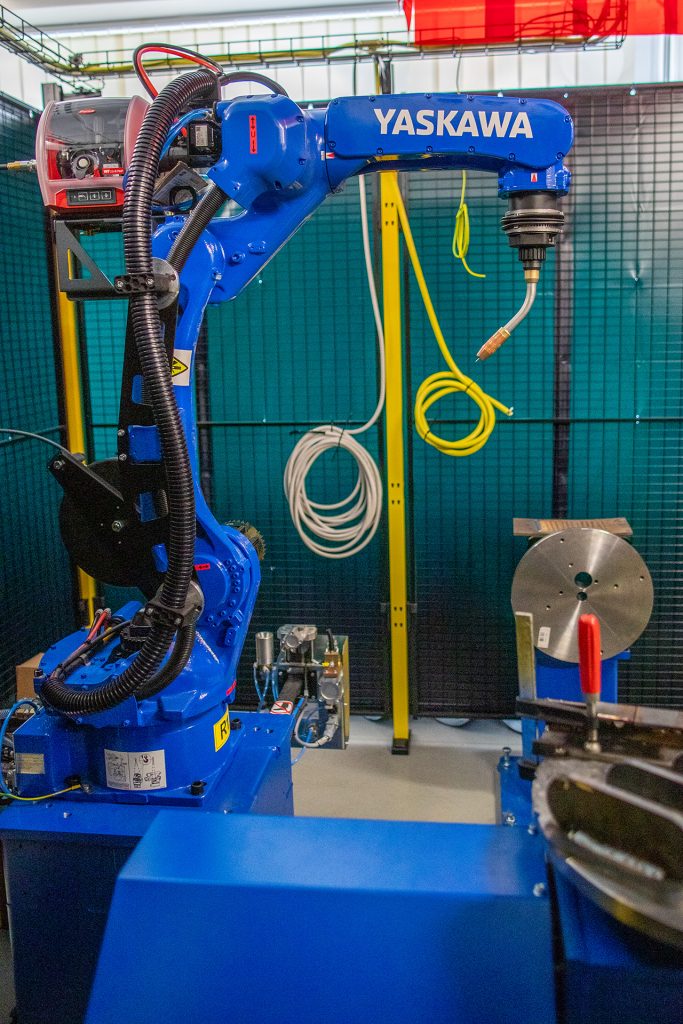

A six-axis Yaskawa industrial welding robot was installed in the third quarter of 2021. The robot will be used to teach students the basics of welding technology, in addition to pathway programming. The equipment will also enable both BSc and MSc, as well as colleagues in doctoral studies in cyber-physical systems, to participate in advanced Industry4.0 research.

The welding procedures taught are:

- Solid wire electrode, active gas shielded arc welding – MAG (135),

- Tungsten arc welding (142)

- Arc welding (111)

- Oxy-acetylene flame welding (311)

- Resistance spot welding (21)

- Submerged arc stud welding (78)

Thermal cutting processes taught:

- Flame cutting (81)

- Plasma cutting (83)

The equipment in the lab consists of Telwin Interpulse 32 power source for MAG welding, Telwin 400 spot welder, Stalwerk WIG-200 PS manual arc welding/TIG welding, ALUSpotter 6100 stud welder and flame welder.

The range of equipment will be completed by the soon-to-arrive Yaskawa AR1730 welding robot, Yaskawa MT1-250 S2D dual-axis positioning equipment and a Fronius TPS400i power source. With the use of this equipment, the knowledge of advanced robotic manufacturing and Industry 4.0 production basics is now available in the context of Manufacturing Technology.